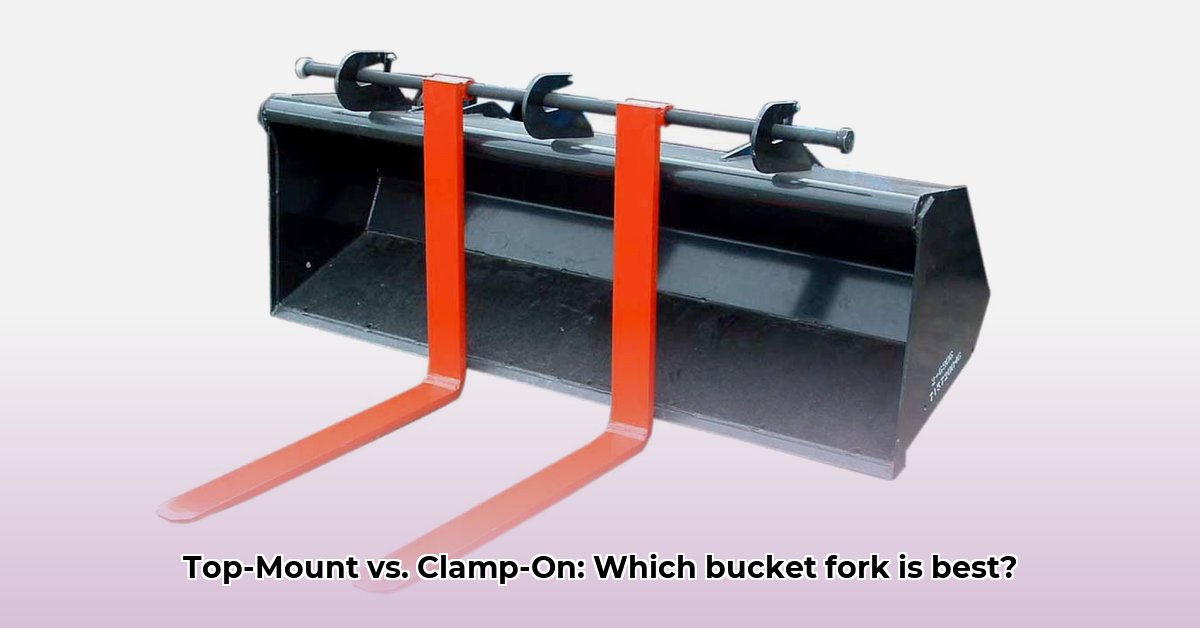

Picking the right bucket forks significantly impacts your tractor's efficiency and safety. This guide compares top-mount and clamp-on forks, helping you choose the best option for your needs. We'll analyze features, costs, and installation, providing a clear decision-making framework. For more options, check out these tractor forks.

Top-Mount Bucket Forks: Strength and Stability

Top-mount forks integrate directly with your tractor's loader, offering superior strength and stability (think of it as a permanent, solid connection). This makes them ideal for heavy lifting and frequent use. Brands like All-Pro are known for their robust designs and relatively easy installation.

Pros:

- Exceptional strength and durability, minimizing the risk of bending or breaking under stress.

- Enhanced stability, reducing the risk of accidents during operation. This is especially crucial when handling heavy loads.

- Generally easier and faster installation compared to clamp-on options. Reduced downtime means increased productivity.

- Improved visibility of the load, enhancing safety and precision during material handling.

Cons:

- Higher initial cost compared to clamp-on alternatives.

- Installation might require specialized tools or professional assistance, adding to the overall expense. The complexity of installation varies depending on the model and tractor.

Clamp-On Bucket Forks: A Budget-Friendly Solution

Clamp-on forks, readily available at retailers like Home Depot, attach to your existing bucket. This provides a cost-effective entry point, but with certain compromises.

Pros:

- Lower initial purchase price, making them accessible to farmers with tighter budgets.

- Simple and quick installation; typically only requiring basic tools. Quick setup is ideal for short-term projects.

Cons:

- Reduced stability compared to top-mount forks. This increases the risk of instability, especially when lifting heavier items.

- Potential for slippage or instability with heavy loads, demanding cautious operation.

- May reduce visibility of the load due to the bucket obscuring the view.

- Compatibility may be limited; they might not fit all tractors and loaders, so always check specifications before purchase.

Comparative Analysis: Top-Mount vs. Clamp-On

This table summarizes the key differences:

| Feature | Top-Mount Forks | Clamp-On Forks |

|---|---|---|

| Cost | Higher initial investment | Lower initial cost |

| Strength | Superior; designed for heavier loads | Lower; suitable for lighter loads |

| Stability | Excellent; provides secure attachment | Lower; greater risk of instability |

| Installation | Generally easier and faster | Simpler but may require adjustments |

| Compatibility | Requires specific model matches to your loader | More widely compatible, but verify specifications |

| Load Center | Lower, enhancing stability | Higher, potentially reducing stability |

| Visibility | Better; improved operator awareness | Reduced; can hinder precise load placement |

Decision-Making Framework: Choosing the Right Forks

Assess your lifting needs: What's the heaviest load you'll regularly lift? Frequent heavy lifting demands the superior strength of top-mount forks. Occasional light use might justify the cost savings of a clamp-on option.

Check tractor compatibility: Always consult your tractor's manual to ensure compatibility with both the weight and physical dimensions of the forks. Ignoring this step could lead to safety issues.

Budget considerations: Top-mount forks represent a higher upfront cost but often translate to lower long-term expenses due to increased durability and longevity. Clamp-on forks provide an immediate cost advantage but may necessitate more frequent replacements.

Maintenance expectations: Both types require regular inspection. Top-mount forks, because of their more robust build, might need less frequent maintenance and replacements.

Potential Problems and Mitigation Strategies

| Potential Problem | Top-Mount Forks | Clamp-On Forks | Mitigation Strategies |

|---|---|---|---|

| Installation Errors | Less Likely | More Likely | Follow instructions meticulously; professional installation advised. |

| Structural Failure | Less Likely | More Likely | Regular inspections; avoid overloading; adhere strictly to weight limits. |

| Compatibility Issues | Possible | Highly Possible | Verify compatibility before purchase; consult with a dealer. |

| Increased Load Center | Lower Impact | Higher Impact | Operate cautiously, aware of shifting weight distribution. |

| Increased Turning Radius | Lower Impact | Higher Impact | Operate with extra care, considering the increased turning radius. |

Remember, the best choice depends on your unique needs. Consulting with a local equipment dealer is highly recommended for personalized advice. They can help you select the optimal bucket forks to enhance your farm's productivity and safety.